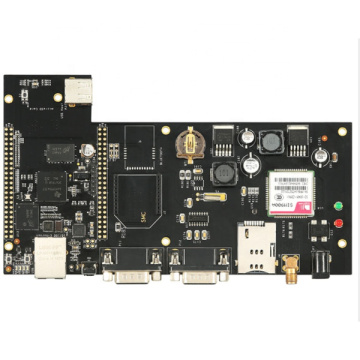

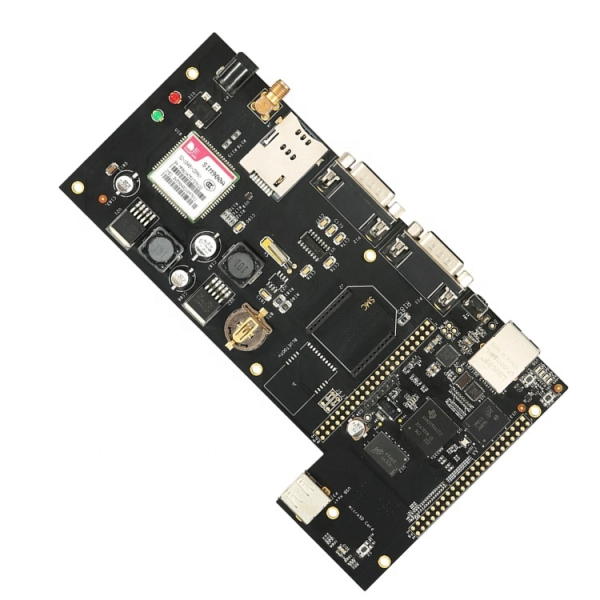

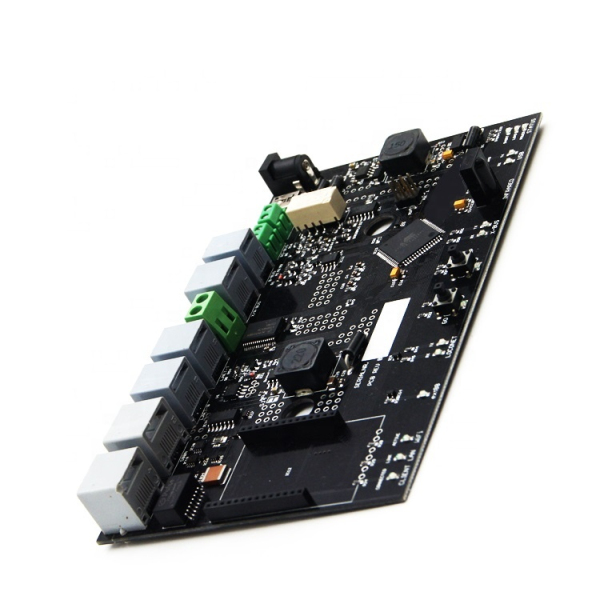

Surface Mount SMT PCB Assembly Service

Basic Info

Model No.: PCB Assembly Express

Product Description

What is PCB Assembly services?

The PCBA Manufacturing or custom pcb fabrication process of printed circuit boards (PCBs) includes many steps. All these steps should go hand in hand to achieve good PCB assembly (Pcba).

The steps involved in the PCB assembly process

The PCBA and manufacturing process involve many steps. If you want to obtain the best quality final product, follow these steps:

Step 1: Add solder paste: This is the initial stage of the assembly process. At this stage, solder paste is added to the electronic components pads wherever soldering is required. Put the solder paste on the pad and paste it in the correct position with the help of the soldering screen. This screen is made of PCB files and has holes.

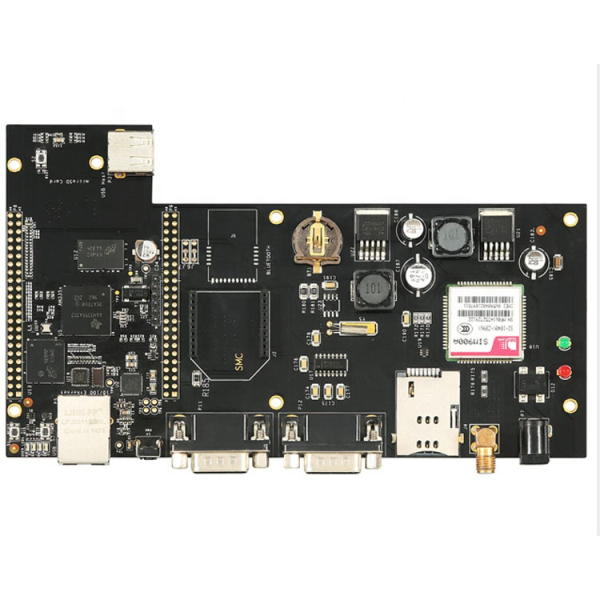

Step 2: Place the component: After adding the solder paste to the component pad, it is time to place the component. The PCB passes through a machine that precisely places these components on the pads. The tension provided by the solder paste holds the components in place.

Step 3: Wave Solder for PCBA: This step is used to permanently fix the component on the board. After placing the components on the board, the PCB passes through the reflow oven conveyor belt. Pass the PCB through the molten solder wave. This will establish electrical connections between the solder, PCB pads and component leads.

Step 4: Cleaning: Up to this step, all the Surface-Mount (SMT) &BGA Assembly processes have been completed. During the soldering process, a large amount of flux residues will be formed around the solder joints. Use deionized water and solvents to clean the flux residues. Through this step, PCB assembly is completed.

Step 6: Testing: At this stage, PCBA Manufacturing is completed and inspections are started to test the location of the components.

Contact us if you need more details on 24 Hour Turnaround Quick. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PCB Service Pcba Assembly、Quickturn PCB Prototype Assembly. If these products fail to match your need, please contact us and we would like to provide relevant information. The steps involved in the PCB assembly process

The PCBA and manufacturing process involve many steps. If you want to obtain the best quality final product, follow these steps:

Step 1: Add solder paste: This is the initial stage of the assembly process. At this stage, solder paste is added to the electronic components pads wherever soldering is required. Put the solder paste on the pad and paste it in the correct position with the help of the soldering screen. This screen is made of PCB files and has holes.

Step 2: Place the component: After adding the solder paste to the component pad, it is time to place the component. The PCB passes through a machine that precisely places these components on the pads. The tension provided by the solder paste holds the components in place.

Step 3: Wave Solder for PCBA: This step is used to permanently fix the component on the board. After placing the components on the board, the PCB passes through the reflow oven conveyor belt. Pass the PCB through the molten solder wave. This will establish electrical connections between the solder, PCB pads and component leads.

Step 4: Cleaning: Up to this step, all the Surface-Mount (SMT) &BGA Assembly processes have been completed. During the soldering process, a large amount of flux residues will be formed around the solder joints. Use deionized water and solvents to clean the flux residues. Through this step, PCB assembly is completed.

Step 6: Testing: At this stage, PCBA Manufacturing is completed and inspections are started to test the location of the components.

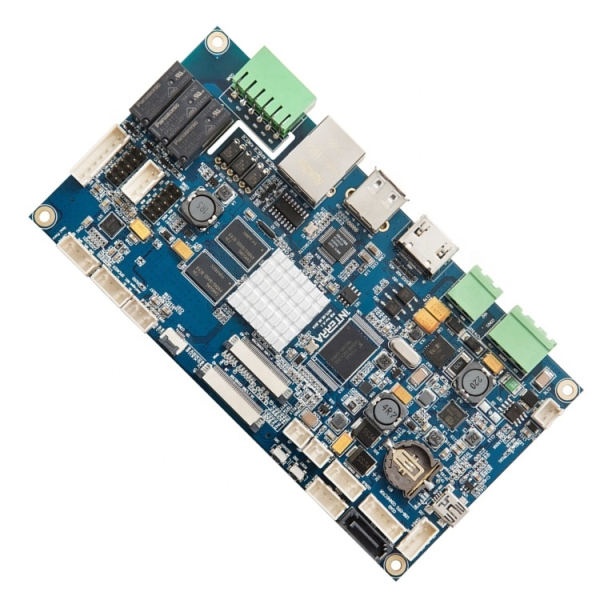

Product Categories : PCB Assembly Products > Through-Hole Assembly